ROTOMOLDING ANIMATION

DESIGN PROCESS VIDEO

.

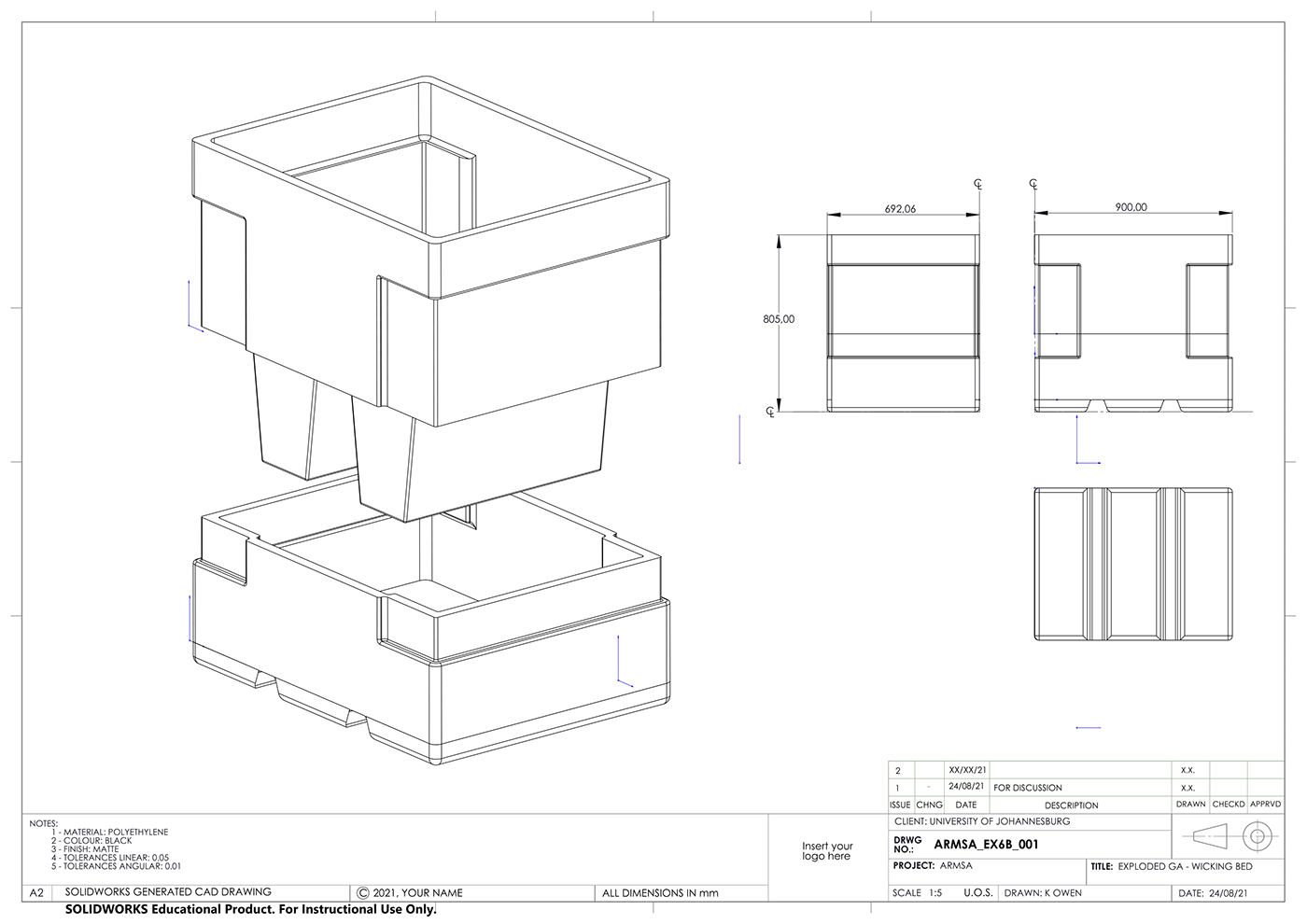

PRINTED PROTOTYPE

The adhesive base at the bottom of the 3D model was too infused to the model and so to avoid damaging the model too much by attempting to remove all of it, I sanded the bottom and filled in holes and gaps with quickset putty and then repainted it.

The first mold was made from RTV silicone, and poured into a cardboard box over the 3D printed model.

But because of gravity, the silicone on top of the model had thinned considerably and tore. I then painted on excess silicone I had left on top of the mold to thicken it. The inside mold, which had been poured inside the model and then flipped upside down, created air pockets at the top and had leaked out. Overall the first attempt at the mold was unsuccessful.

The second attempt at a mold I tried liquid rubber, which required me to paint layers on the model until a thick coat had cured around the model.

The rubber mold had come out too flexible and so I came to the conclusion that I needed to work with a much smaller prototype, and apply a reinforcement inbetween layers.

Using the smaller prototype - aproximately 50% the size of the first 3D printed prototype - I made another rubber mold using the liquid rubber with nylon mesh placed in between layers to strengthen the structure. The mold is brushed with tulc powder after its cured and then painted over the outside with super glue to completely stiffen it.

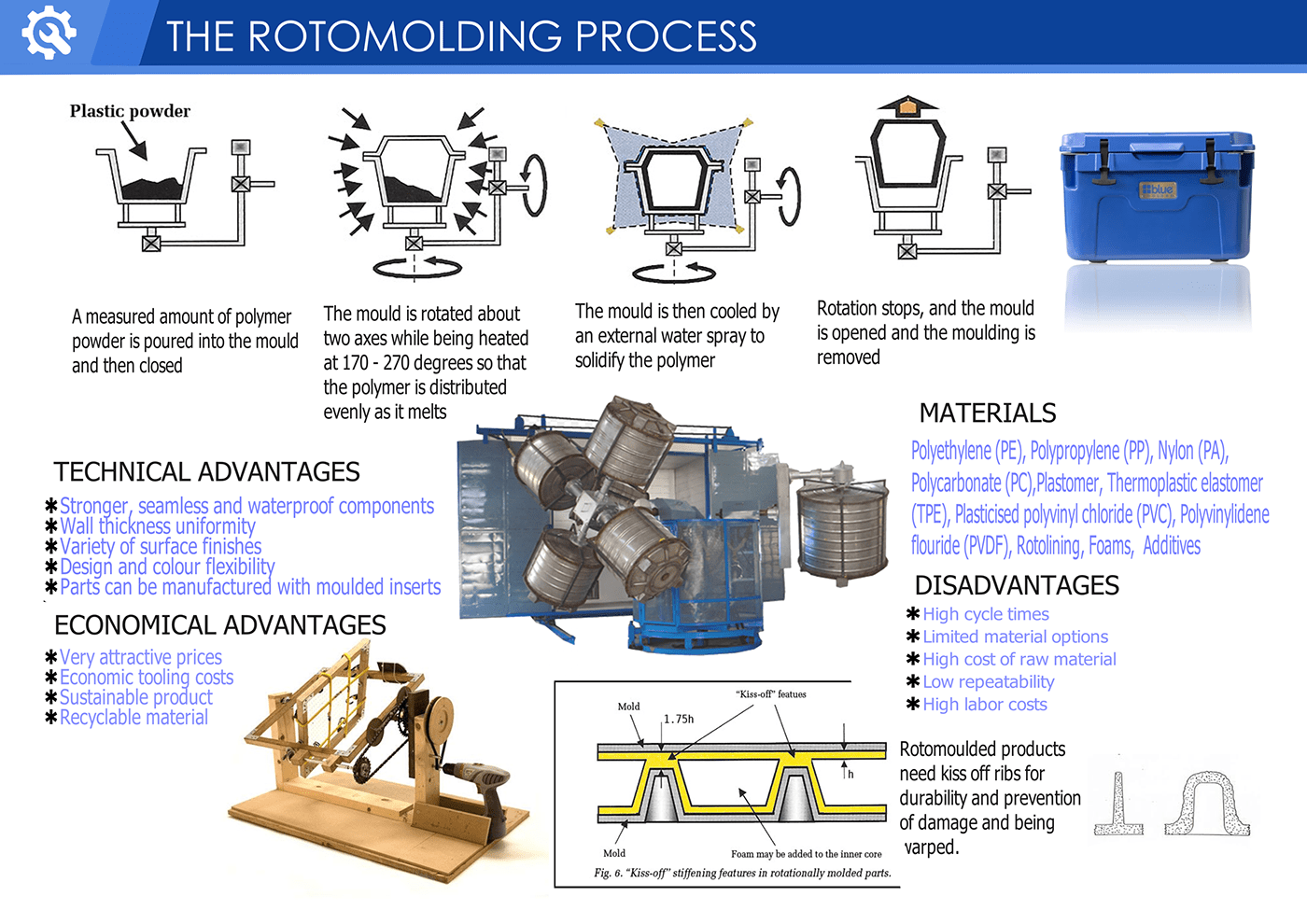

Rotomolding

First I brushed off the inside of either mold with baby powder, I did not powder the base flanges so that they stay tacky and stick a little when I applied pressure. This was so the resin wouldn't leak out any gaps whilst rotomolding.

I poured the measured smooth cast resin into the mold, and then carefully aligned the top part of the mold with the bottom, making sure the wall thickness was equal all round. Once aligned I used bobby pins to secure the molds together, I then placed cardboard on either side of the mold and secured those with rubber bands.

I rotomolded the piece by hand for about 10 minutes and then peeled the latex mold off of the resin. The resin was still a little tacky so I left it for another 15 minutes to dry.

.

.